Getting to the Fret-boards

This section deals with building custom fret-boards for finely crafted guitars.

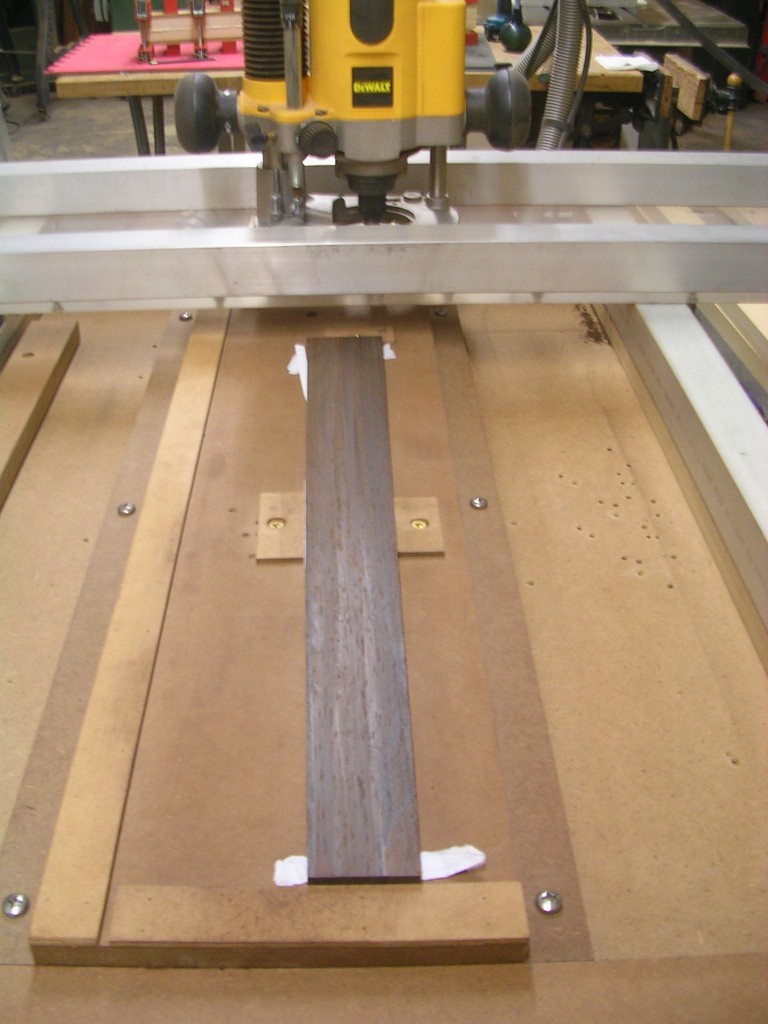

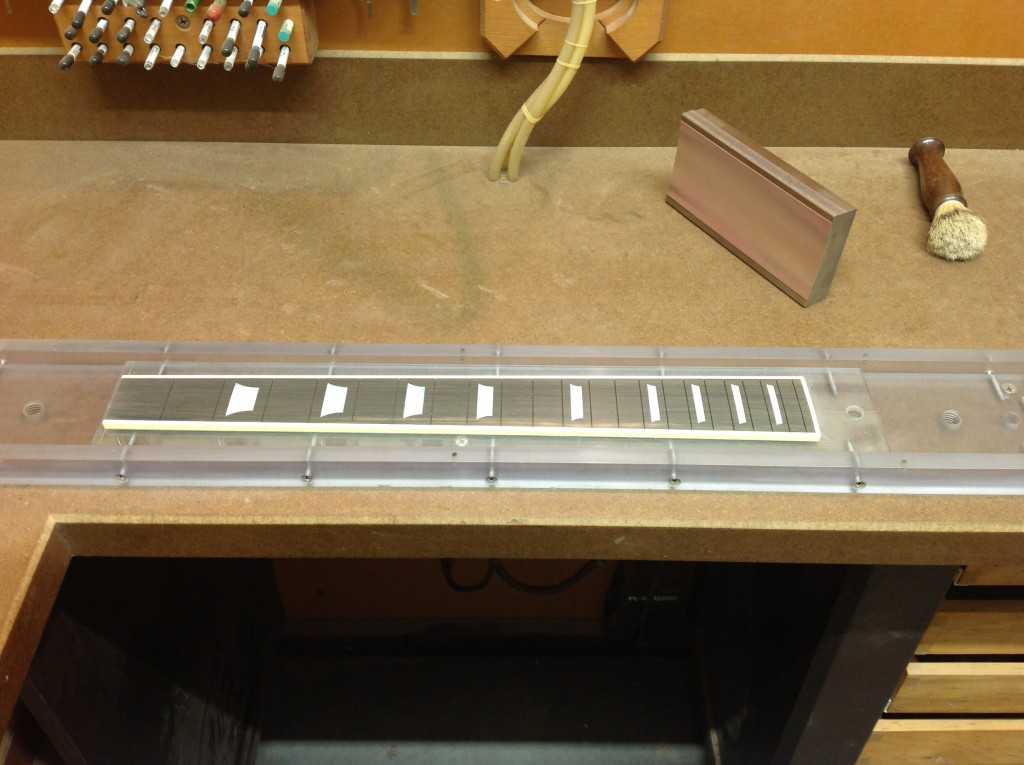

Beneath is a Brazilian rosewood fret-board in the router skimmer, being flattened and and brought down to final thickness.  Here is the aforementioned board getting slotted for frets on the table saw with the fret slotting jig.

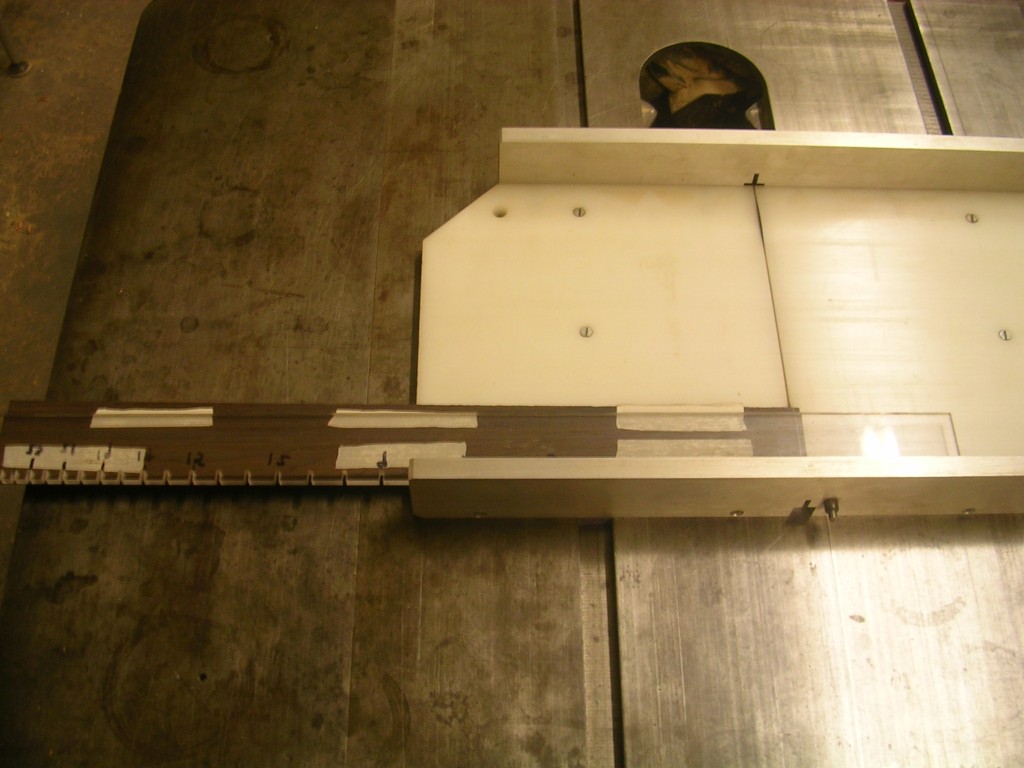

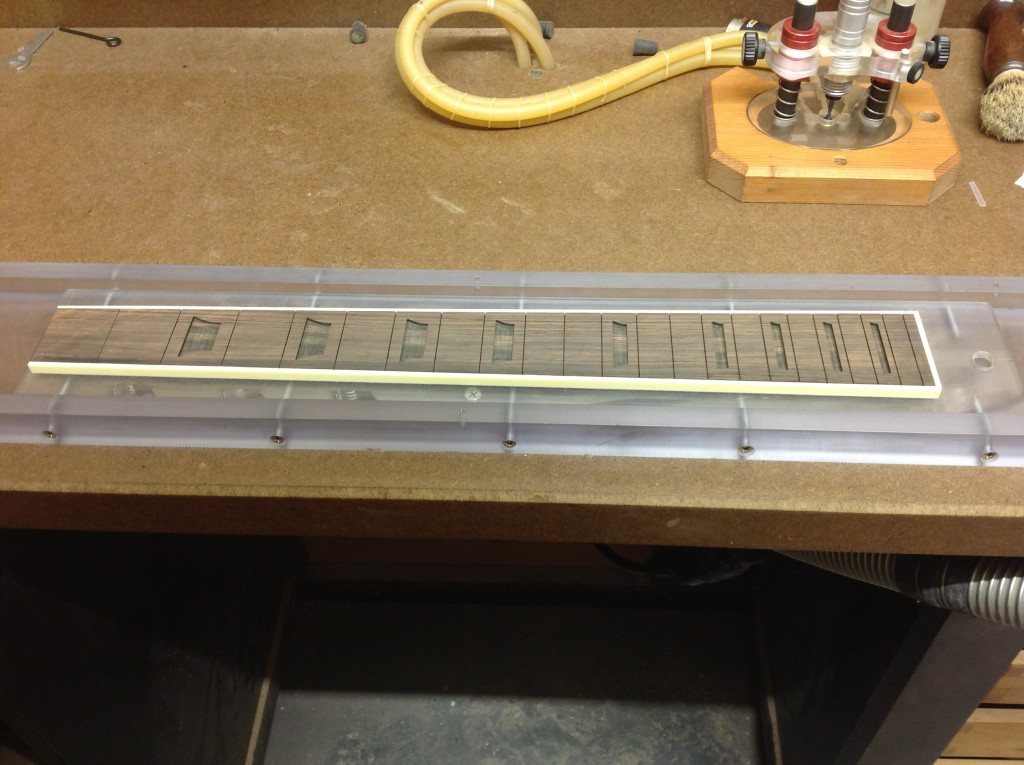

Here is the aforementioned board getting slotted for frets on the table saw with the fret slotting jig.  Here are the fretboards, slotted, cut to size and bound. The methods for bounden will be covered in the cervix building section. These boards are ready for inlay.

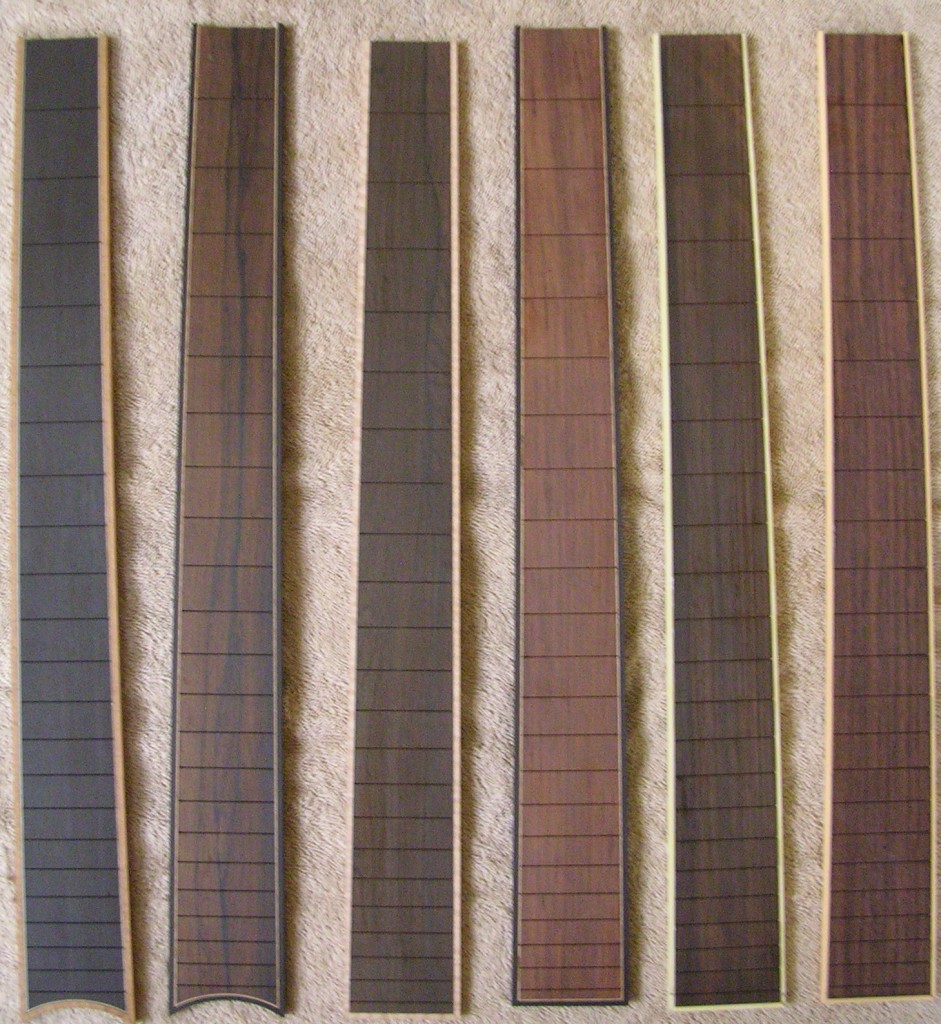

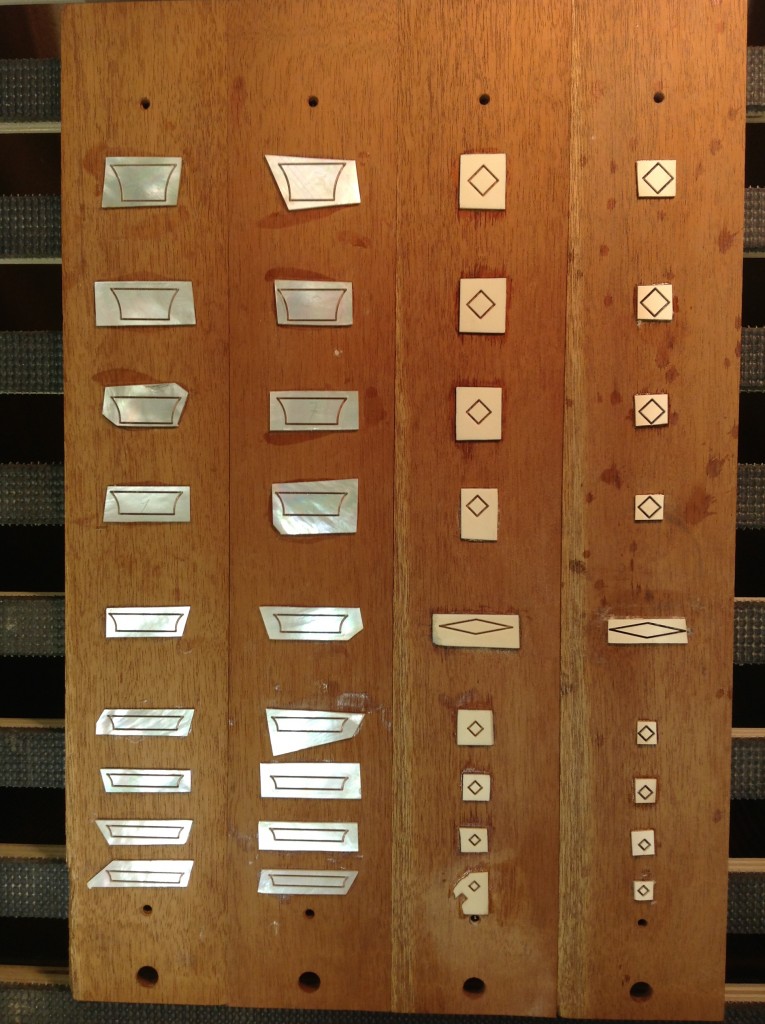

Here are the fretboards, slotted, cut to size and bound. The methods for bounden will be covered in the cervix building section. These boards are ready for inlay.  The inlay materials (in this example, mammoth ivory and MOP) accept been slabbed and are ready to be cut. Here is a shot of mammoth ivory inlay blanks glued to the cut board, along with the jig cradle and the diamond inlay cut jig.

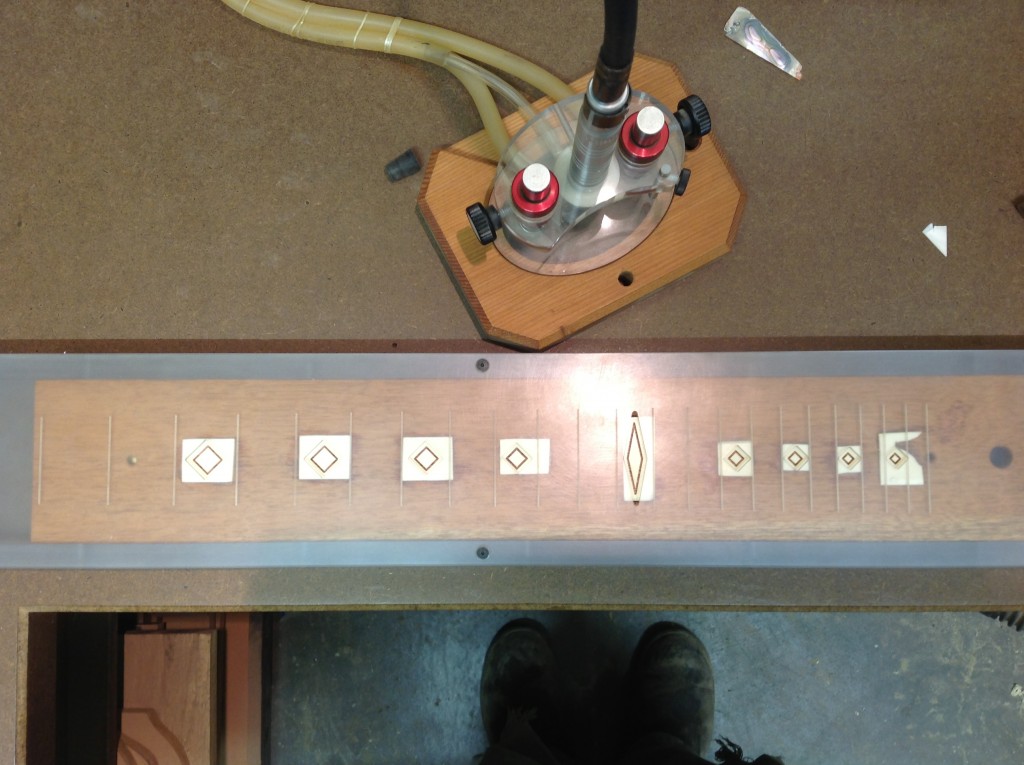

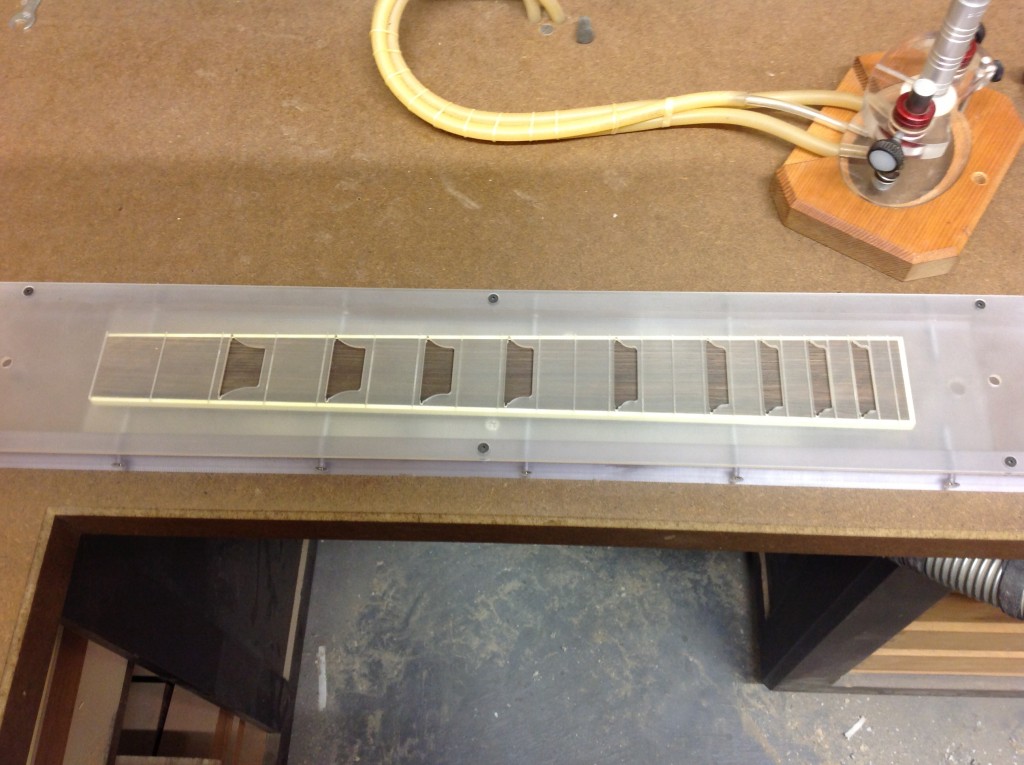

The inlay materials (in this example, mammoth ivory and MOP) accept been slabbed and are ready to be cut. Here is a shot of mammoth ivory inlay blanks glued to the cut board, along with the jig cradle and the diamond inlay cut jig.  Here it is with the jig assembled, all prepare to get. The cutting board locates in the cradle by means of pins and the Plexiglas template is screwed to the cradle.

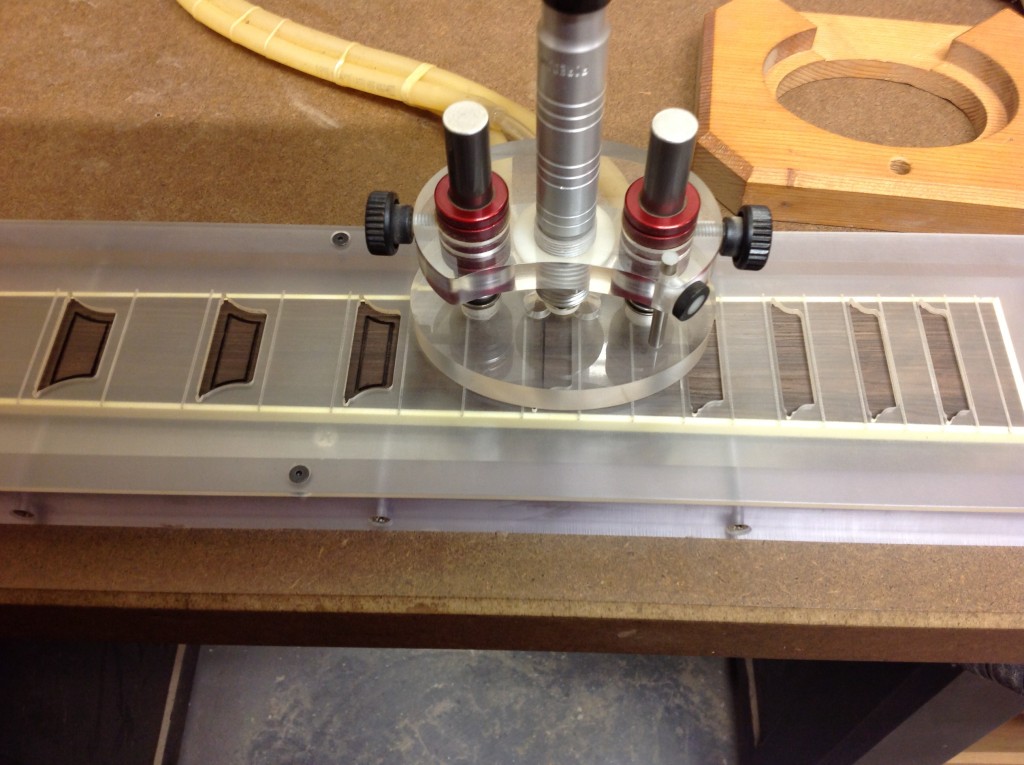

Here it is with the jig assembled, all prepare to get. The cutting board locates in the cradle by means of pins and the Plexiglas template is screwed to the cradle.  Hither is a close up of the router. Hither you lot can see the three/16″ collet that will ride the edges of the cut jig, creating the inlay pieces. Also note here the 2 vacuum ports and the blower port. The blower port is attached by ways of surgical tubing to an aquarium manner blower.

Hither is a close up of the router. Hither you lot can see the three/16″ collet that will ride the edges of the cut jig, creating the inlay pieces. Also note here the 2 vacuum ports and the blower port. The blower port is attached by ways of surgical tubing to an aquarium manner blower.

This gentle airstream blows right into the collet, keeping the collet from getting clogged with gooey rosewood dust and also acts every bit a coolant, extending chip life and giving cleaner results. The vacuum ports are attached by means of surgical tubing to a vacuum. This is obviously for removing dust from the extremely confined area, works slap-up. An unexpected bonus here was that the vacuum ports also work every bit a agree down for the router. I can let go of the router at anytime whilst routing at total speed and the router stops dead and sits nevertheless with no ill upshot. The concord downwardly effect also steadies the router while routing, giving more consistent results.

Cutting Inlays for Woodworking

Here it is role fashion through the first pass. The first pass is done with the .040″ bit.  Here it it is later the second pass.

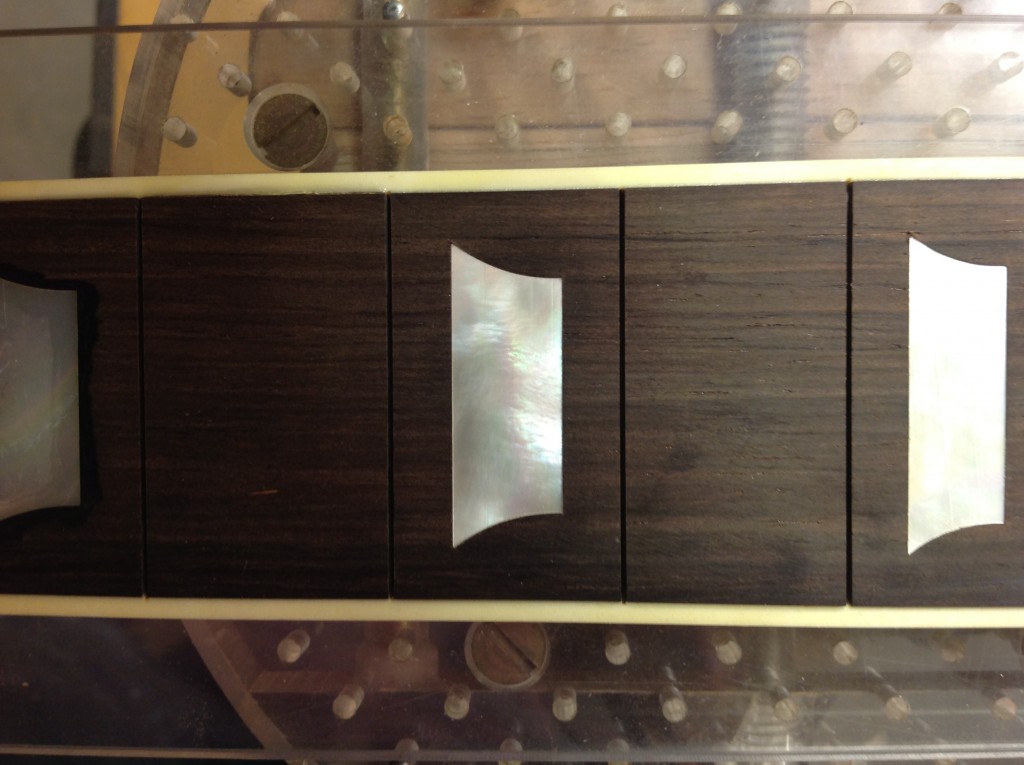

Here it it is later the second pass.  The 2nd pass is done with the.045″ bit as a cleanup pass. This chip is a 4 flute flake cutting simply .0025″ and leaves a remarkably clean edge for a hand operated tool. Below is a shut up of the 12th fret inlay every bit a demonstration of this.

The 2nd pass is done with the.045″ bit as a cleanup pass. This chip is a 4 flute flake cutting simply .0025″ and leaves a remarkably clean edge for a hand operated tool. Below is a shut up of the 12th fret inlay every bit a demonstration of this.

Hither are trapezoid inlays being cut for a Certified 7. Same process here with a slightly slower feed charge per unit for shell fabric, which is much harder.  Cut consummate.

Cut consummate.

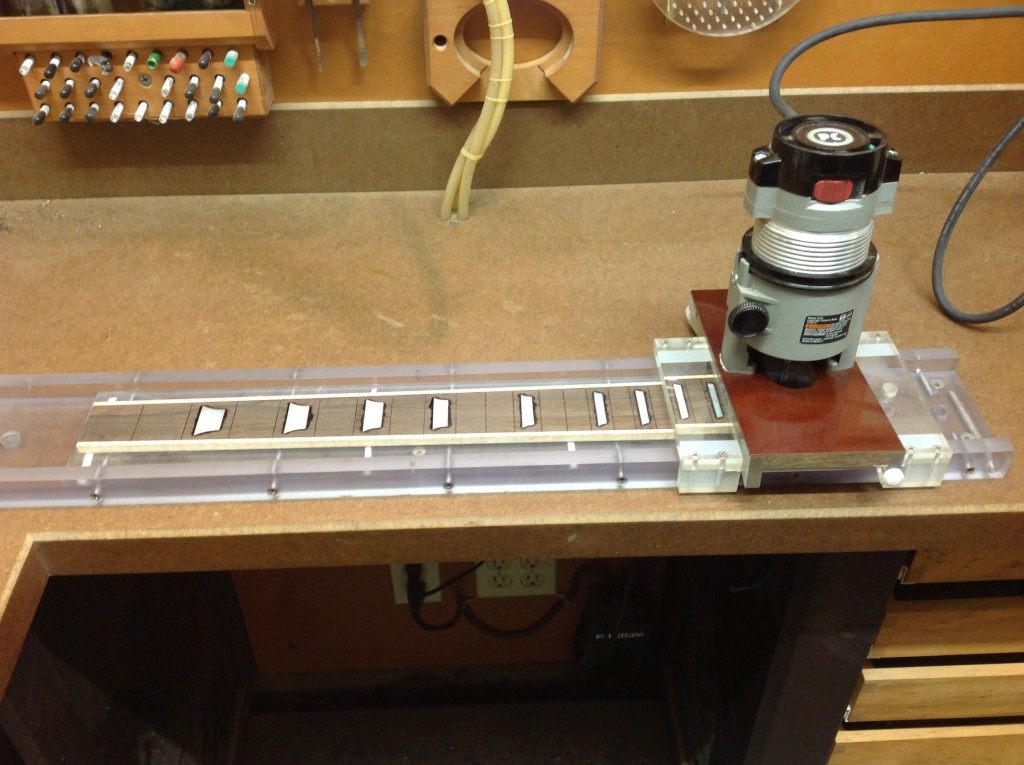

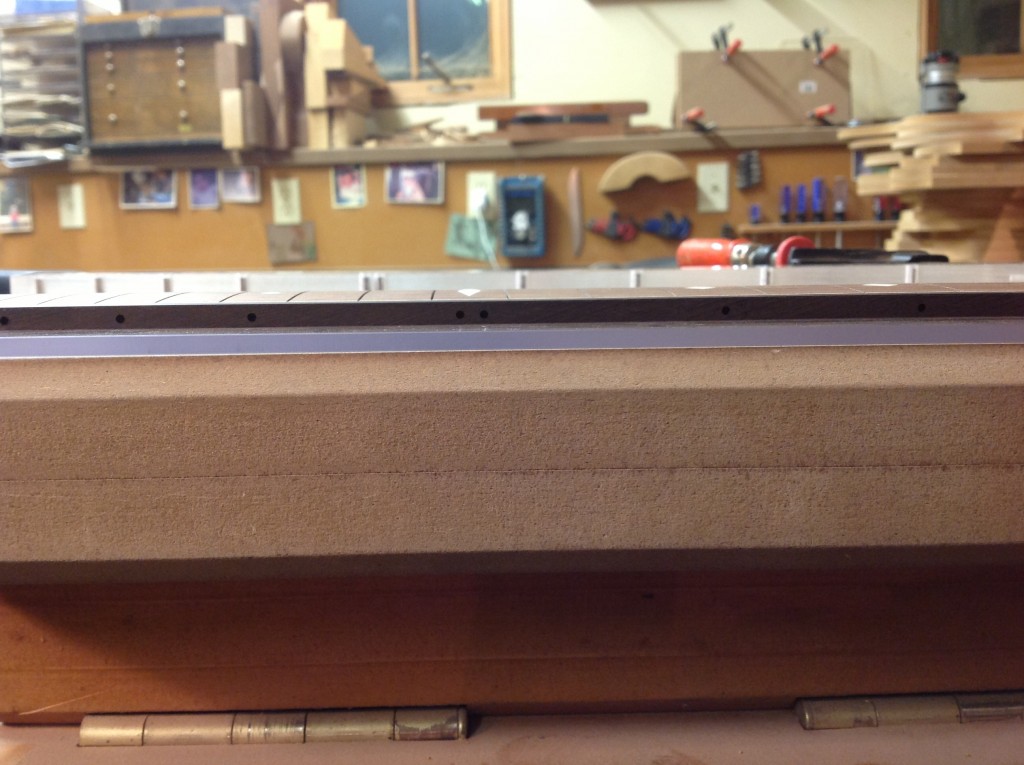

Here's the same jig used to cut the inlay pieces with a Brazilian Rosewood fretboard, two-face taped to a plexiglass work board which locates with the same pins, set to have the pockets cut for the inlay pieces.

Here's the same jig used to cut the inlay pieces with a Brazilian Rosewood fretboard, two-face taped to a plexiglass work board which locates with the same pins, set to have the pockets cut for the inlay pieces.

I use the same template and the aforementioned router heads and $.25 to accomplish the pockets. The difference here is that I demand to bring the path of the cutter in to account for the width of the fleck. If I don't do this the inlay would be swimming around in the pocket. This is accomplished by means of a secondary collet that slips over the primary collet which is fixed to the router base. In the photo below y'all can run into the secondary collet which is made of statuary. I made several of these secondary collets in .001″ increments. Some species react differently to the cut due to density and grain differences. You'd exist surprised what a few thousandths difference will make.

I use the same template and the aforementioned router heads and $.25 to accomplish the pockets. The difference here is that I demand to bring the path of the cutter in to account for the width of the fleck. If I don't do this the inlay would be swimming around in the pocket. This is accomplished by means of a secondary collet that slips over the primary collet which is fixed to the router base. In the photo below y'all can run into the secondary collet which is made of statuary. I made several of these secondary collets in .001″ increments. Some species react differently to the cut due to density and grain differences. You'd exist surprised what a few thousandths difference will make.  Office mode through starting time pass.

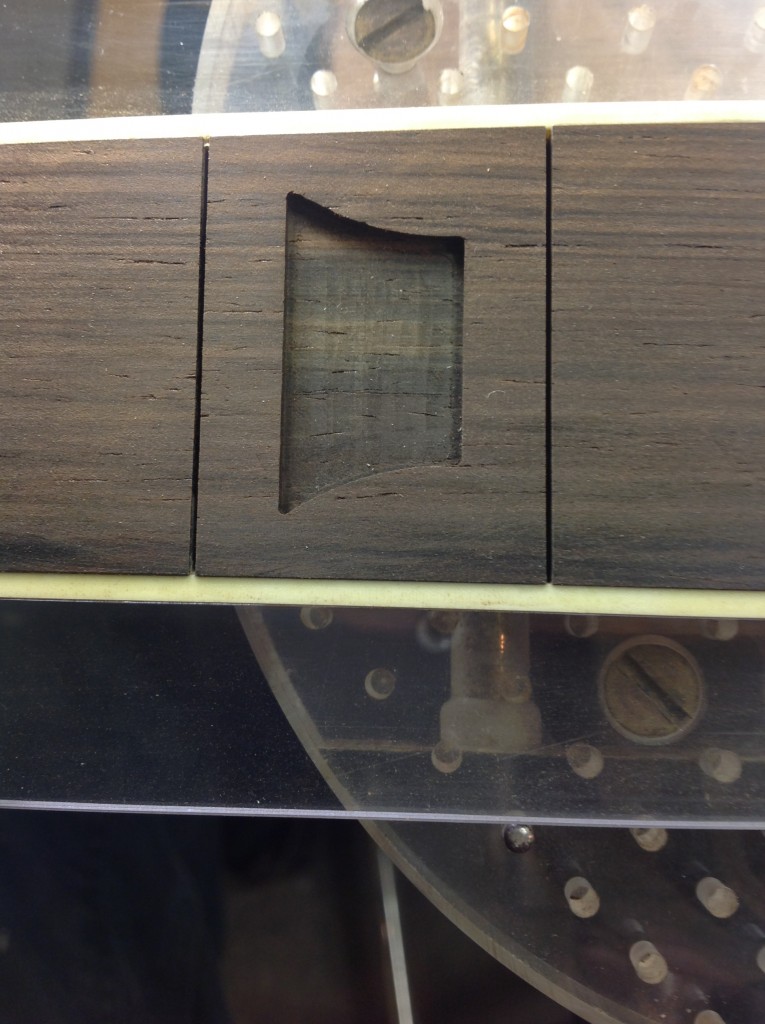

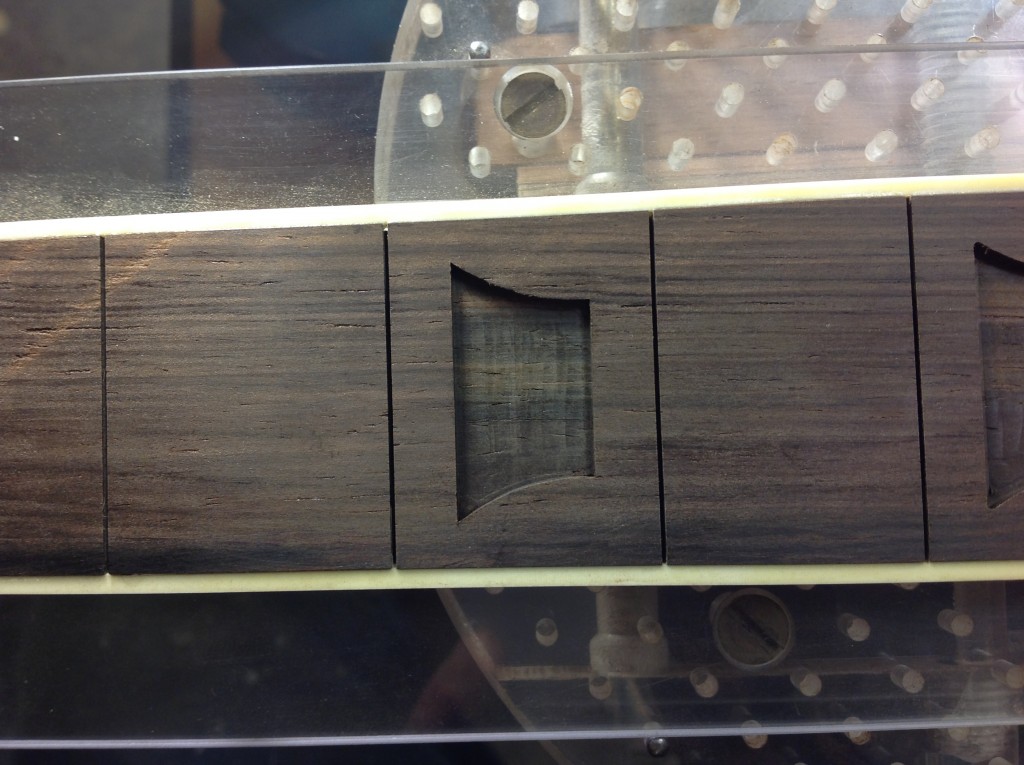

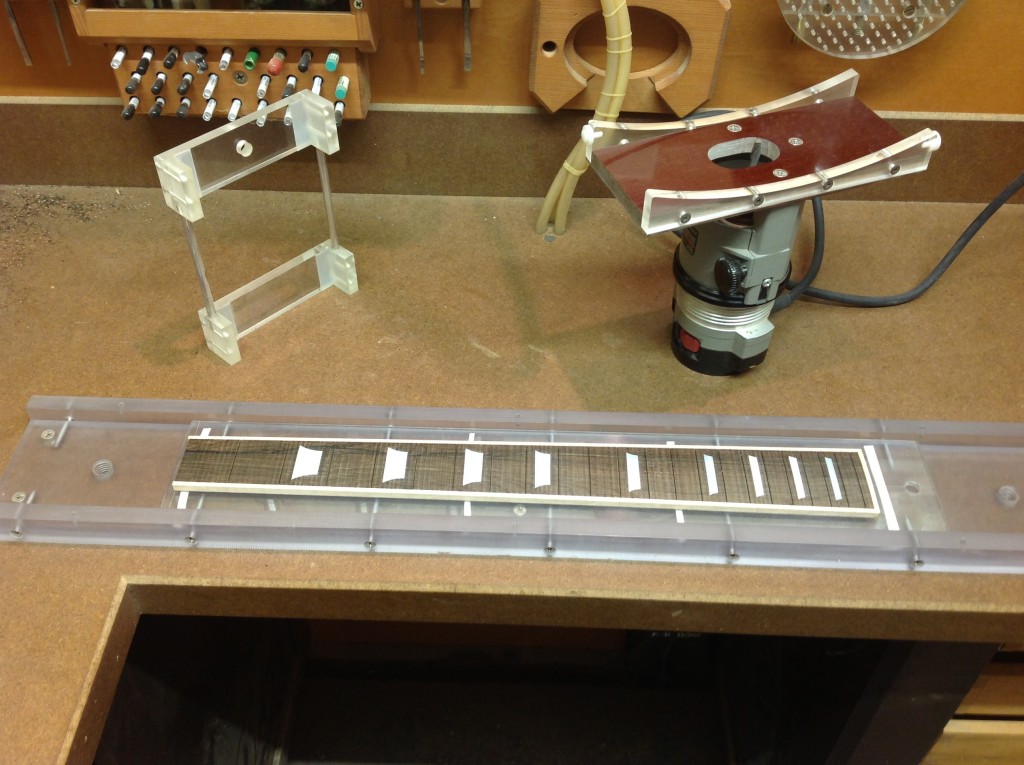

Office mode through starting time pass.  The second pass is once more done with the .045″ bit, which is cutting but .0025″ of material, leaving an incredibly clean edge on the pocket. When the perimeter of the pockets are cutting, I switch over to a unlike router setup to remove the remaining material. This router is equipped with a 1/viii″ bit and a larger collet setup. This saves time and keeps the smaller cutters from breaking or dulling.

The second pass is once more done with the .045″ bit, which is cutting but .0025″ of material, leaving an incredibly clean edge on the pocket. When the perimeter of the pockets are cutting, I switch over to a unlike router setup to remove the remaining material. This router is equipped with a 1/viii″ bit and a larger collet setup. This saves time and keeps the smaller cutters from breaking or dulling.  Here are the pockets all routed.

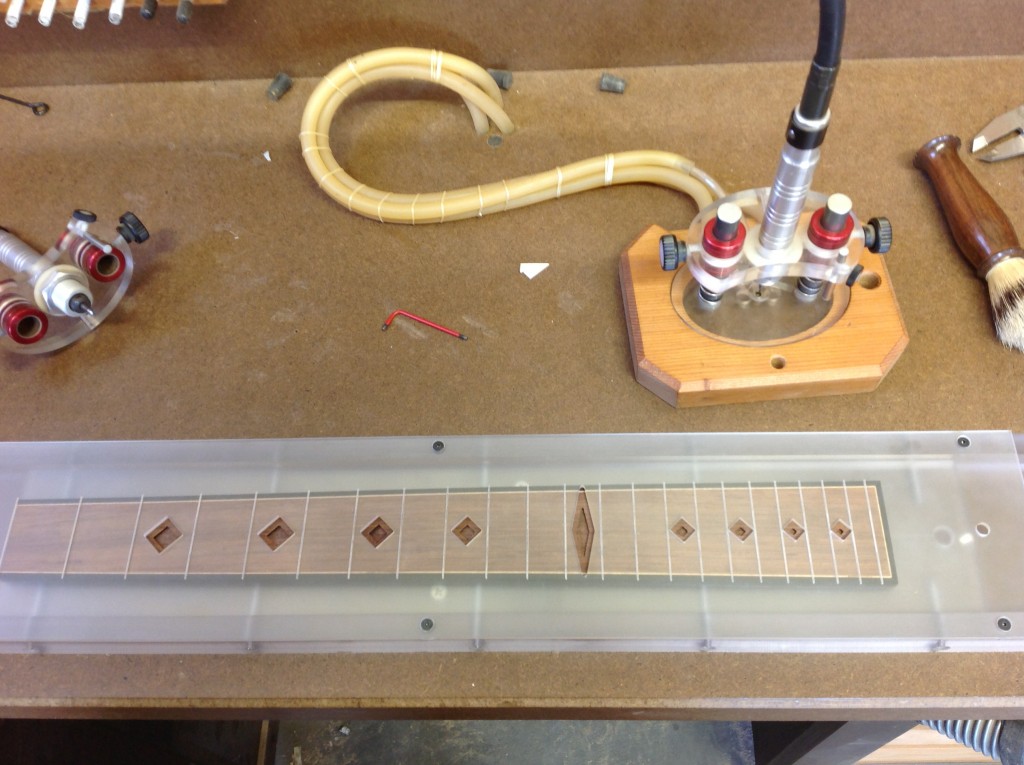

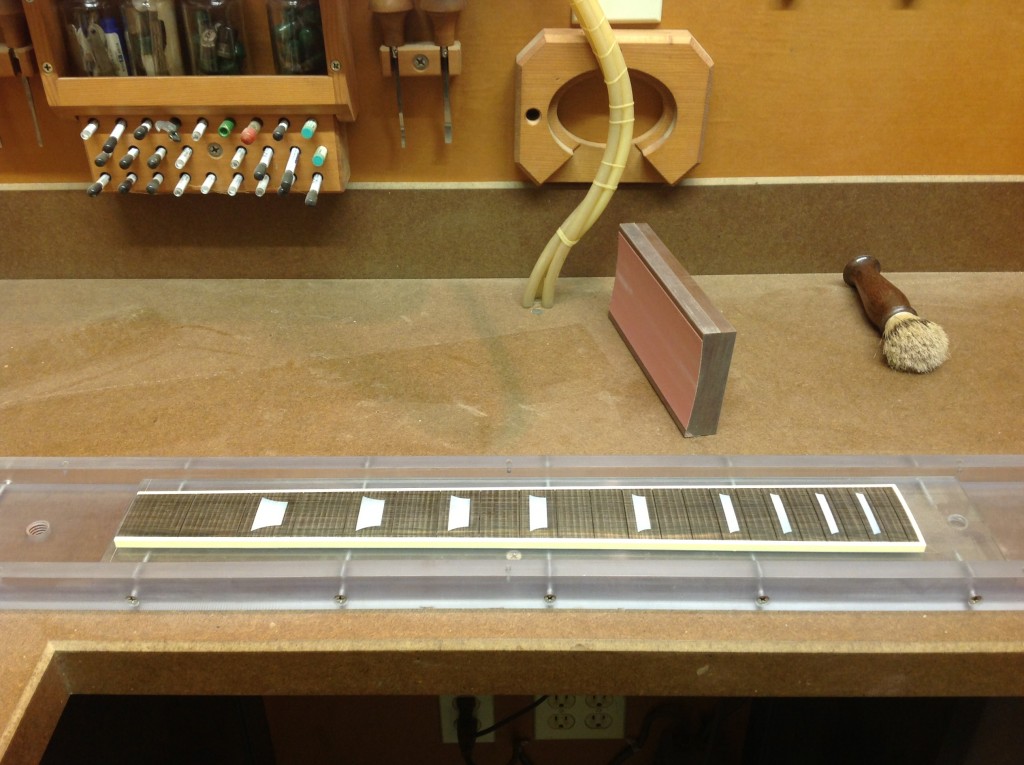

Here are the pockets all routed. Here are some shots of a Madagascar rosewood fretboard getting the aforementioned treatment for mammoth ivory diamond inlays.

Here are some shots of a Madagascar rosewood fretboard getting the aforementioned treatment for mammoth ivory diamond inlays.

Hither they are afterward the pockets accept been routed.

Hither they are afterward the pockets accept been routed.

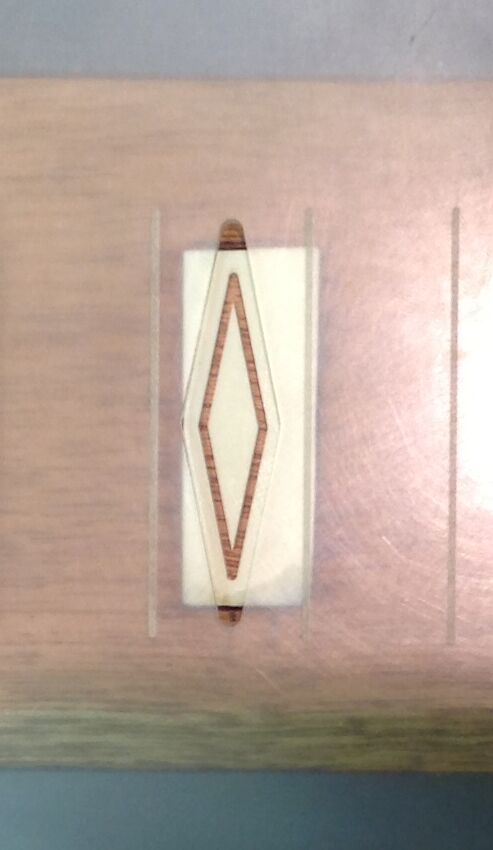

This method leaves me with a footling paw work to sharpen the rounded corners left by the radius of the cutter. I practise this with either a tiny chisel or a modified x-acto pocketknife. Below are before and after shots of a twelfth fret diamond and A 5th fret trapezoid inlay.

Here's the lot. Routed, corners cleaned and ready for inlay.

Here's the lot. Routed, corners cleaned and ready for inlay.  Here's an instance of how authentic this system is. Inlay piece installed, nice tight fit with gentle pollex pressure. This is a seventh fret inlay.

Here's an instance of how authentic this system is. Inlay piece installed, nice tight fit with gentle pollex pressure. This is a seventh fret inlay.

Hither are a few shots of a custom chocolate mammoth ivory 12th fret inlay. This design is besides complicated to utilize the above system of templates and cutters, so information technology'due south dorsum to the old school on this one. The methods used hither will exist covered in the inlaying of the headstock logo in the neck building section.

Here's the lot, inlayed and installed. Boards are ready to exist radiused.

Here's the lot, inlayed and installed. Boards are ready to exist radiused.  Raidiusing fretboards. Here is my radiusing jig. On the correct you can see the router attached to a sled with radiused runners. These runners create the radius past riding on the stainless steel rods that connect the 2 parts of the carriage seen on the left. The wagon snugly fits correct over the jig cradle and slides upwards and downwards the length of the fretboard.

Raidiusing fretboards. Here is my radiusing jig. On the correct you can see the router attached to a sled with radiused runners. These runners create the radius past riding on the stainless steel rods that connect the 2 parts of the carriage seen on the left. The wagon snugly fits correct over the jig cradle and slides upwards and downwards the length of the fretboard.  Here are all the parts of the jig set up to go. The router and sled are moved dorsum to forward and dorsum again to create the radius, and the carriage progresses from correct to left 1 pass at a time.

Here are all the parts of the jig set up to go. The router and sled are moved dorsum to forward and dorsum again to create the radius, and the carriage progresses from correct to left 1 pass at a time.  Hither information technology is later the routing. I use a i/four″ endmill for this operation. Information technology works great for this and even hums right through the pearl with no effort when the $.25 are abrupt.

Hither information technology is later the routing. I use a i/four″ endmill for this operation. Information technology works great for this and even hums right through the pearl with no effort when the $.25 are abrupt.  The lines that are visible now are not deep, merely very shallow surface marks left by the physics of the endmill and how information technology shears the fibers of the forest. These will be sanded out in short lodge with the sanding cake seen below equipped with 400 grit paper.

The lines that are visible now are not deep, merely very shallow surface marks left by the physics of the endmill and how information technology shears the fibers of the forest. These will be sanded out in short lodge with the sanding cake seen below equipped with 400 grit paper.  And there ya take information technology!

And there ya take information technology!  Here's the lot, all sanded and gear up for side dots.

Here's the lot, all sanded and gear up for side dots.  I buy MOP and abalone side dots, but I have to make mammoth ivory dots here in the store. This is washed on the milling motorcar with a rotary table.

I buy MOP and abalone side dots, but I have to make mammoth ivory dots here in the store. This is washed on the milling motorcar with a rotary table.  Here is my side dot drilling jig. Very simple. Just a piece of 3/8″ plexiglass with some well placed drill guide bushings. It lays on the lexan work lath to institute the proper height. Atop the jig yous can meet the dots still glued to the backer wood from the cutting operation.

Here is my side dot drilling jig. Very simple. Just a piece of 3/8″ plexiglass with some well placed drill guide bushings. It lays on the lexan work lath to institute the proper height. Atop the jig yous can meet the dots still glued to the backer wood from the cutting operation.  In the to a higher place photo you can run across the 5/64″ brad point chip used to do the drilling and in the photograph below y'all can encounter the make clean holes the scrap produces.

In the to a higher place photo you can run across the 5/64″ brad point chip used to do the drilling and in the photograph below y'all can encounter the make clean holes the scrap produces.  Here, the dots have been pressed in and glued.

Here, the dots have been pressed in and glued.  The fretboards are now removed from the lexan piece of work boards. A little cleanup on the side dots and the boards are ready meet the necks!

The fretboards are now removed from the lexan piece of work boards. A little cleanup on the side dots and the boards are ready meet the necks!  Rick Maguire

Rick Maguire

⇐ Previous Folio Θ Next Page⇒

0 Response to "How To Make A Fretboard"

Post a Comment